The area of fence stone moulds often involves very complex tasks, frequently with draw sheet design or other downstream production steps as e.g. gap or aging systems. Those challenges require an experienced partner in planning and execution, such as the professionals of ZENITH in the planning and production department:

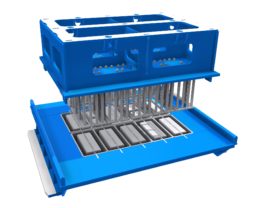

MOULD DESIGN:

- Combination of welded and milled designs

- High quality wear resistant steel

- Shoe clearance 0,5-0,8 mm

- Shoes easily changeable

- Robust and proven design

- Exchange mould feasible

- Easy replacement of wearing parts

- Hydraulic folding wall elements feasible

- Interior parts feasible in nitrated (62-68 HRC) version

We always determine the exact mould design in close cooperation with the customer. When it comes to low stone heights, we might recommend the consultation of the machine manufacturer.